ELECTRICAL POWER SYSTEM PRESENTATION OF AIRBUS

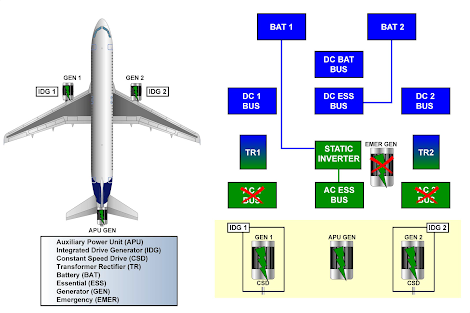

There are two identical engine driven generators called Integrated Drive

Generators (IDGs). They are used as the main power source to supply

the A/C electrical network.

The IDG basically contains, in a common housing, a generator and a

Constant Speed Drive (CSD). The CSD gives a constant input speed to

the generator, which is required for a constant output frequency.

Each generator supplies 115V 400Hz AC to its own bus:

- generator 1 supplies AC bus 1,

- generator 2 supplies AC bus 2.

This supply is known as split operation, which means that the AC power

sources are never connected in parallel.

Each AC bus supplies a Transformer Rectifier (TR):

- AC bus 1 supplies TR 1,

- AC bus 2 supplies TR 2.

The TRs convert 115V AC into 28V DC to supply their associated DC

buses, DC 1 and DC 2.

DC bus 1 then supplies the DC BAT bus.

The DC battery bus can charge the batteries or receive power from the

batteries as a backup supply, if no other power sources are available.

The electrical system also includes two ESSential (ESS) Buses. One is

the AC ESS bus fed by AC bus 1 and the other is the DC ESS bus fed

by DC bus 1. These buses are used to supply the most critical A/C

systems.

This is the basic electrical system. We will now introduce some other

components, which also supply the system.

The entire electrical network can also be supplied by the APU generator.

On the ground, the aircraft electrical network can be supplied by an

external power source.

Any one of the power sources can supply the entire electrical network.

As no parallel connection is allowed on this A/C (split operation), we

have to give priorities to the different power sources in supplying the bus

bars.

AC 1 and AC 2 buses are supplied in priority by their own side generator,

then the external power, then the APU generator and then by the opposite

generator.

ABNORMAL CONFIGURATION

The electrical system has an ESS TR, which supplies the DC ESS

Bus in abnormal or emergency configuration.

In abnormal configuration (loss of TR1 or TR2) the ESS TR is

supplied by the AC ESS Bus.

EMERGENCY CONFIGURATION

In the event of emergency operation, the Emergency Generator (EMER

GEN) supplies the A/C with electrical power. The EMER GEN needs

hydraulic power to operate. This hydraulic power to drive the EMER

GEN is supplied by the Blue Hydraulic system via the Ram Air

Turbine (RAT). The RAT is located in the belly fairing and extends

automatically when AC BUS 1 and 2 have no voltage supply.

Then, the EMER GEN supplies the DC ESS BUS directly through

the ESS TR. In emergency configuration (loss of AC BUS 1 and AC

BUS 2) the EMER GEN supplies the ESS TR.

BATTERY ONLY CONFIGURATION

In emergency configuration with emergency generator not available,

BAT 1 supplies the AC ESS BUS via the static inverter and BAT 2

supplies the DC ESS BUS.

CONTROL AND INDICATING/PANEL LOCATION

The ELEC panel is installed on the overhead panel.

For emergency cases, there is an EMER ELEC PWR panel on the LH

side of the overhead panel.

MAIN PANEL/ECAM PAGE

The ECAM Electric System page shows all relevant data with regard

to the entire A/C Electrical Power Generation and Distribution

systems. The System page shown here is a normal configuration with

main generators supplying the network.

The battery voltage can be monitored either on the overhead panel or

the ECAM page. Each battery is controlled by a P/B Switch (SW).

Their related P/B SW control both main generators and the APU

generator.

A P/B SW also controls the external power.

The AC ESS FEED P/B SW lets the pilots change the supply to the

AC ESS bus from AC bus 1 to AC bus 2.

When the BUS TIE P/B SW is in the AUTO position, it lets the

opening or closing of the bus tie contactors in order to supply the AC

1 and AC 2 buses according to the power supply priorities.

When OFF, both bus tie contactors open to isolate one side of the

network from the other (e.g.: smoke configuration).

In case of failure, the IDG P/B switches disconnect the IDG from the

engine gearbox.

The GALY & CAB P/B SW lets galleys and some sub-buses be

manually shed.

The COMMERCIAL P/B SW is used for the shedding of all

commercial loads including the GALY & CAB related buses.

EMERGENCY PANEL

The EMER GEN TEST P/B is used on ground to test the EMERgency

GENerator or the Static Inverter.

In avionics smoke condition, the GEN 1 LINE P/B disconnects the

generator 1 from the busbar but the generator remains excited to supply

some fuel pumps.

When AC BUS 1 and 2 are no longer supplied, the RAT will extend

automatically to pressurize the blue hydraulic system, which powers

the EMER GEN, if the A/C speed is sufficient.

WARNING: ACTIVATION OF THE RED GUARDED MAN ON

PUSHBUTTON ON THE GROUND OR IN FLIGHT

WILL EXTEND THE RAM AIR TURBINE (RAT),

EVEN ON COLD AIRCRAFT.

COMPONENT LOCATION

The AC generators supply a 115 VAC, 3-phase, 400 Hz AC supply. The

IDGs and the APU have a nominal 90 kVA power whereas the EMER

GEN has a 5 kVA output.

The static inverter converts the direct current from battery 1 into an AC

current if no other source is available.

The Battery Charge Limiters (BCLs) control the battery coupling and

uncoupling to the DC BATTERY BUS to ensure battery charging and

protection. Each battery is rated at 24 V with a capacity of 23 Ah. All

TRs are identical and interchangeable.

In the Enhanced Electrical Power Generation System (EPGS), the GAPCU

controls the APU GEN and the external power. The Generator Control

Units (GCUs) protect and control the A/C network and generators. GCUs

and GAPCU supply AC electrical power parameters to show them on

the ECAM display. The main C/B panels are located in the cockpit.

The ESS TR is identical to TR 1 and TR 2. It converts 115 VAC to 28

VDC at a rate of 200 A. The EMER GCU connects the EMER GEN to

the ESS network, if all conditions are met.

The Ground Power Control Panel and the external power receptacle are

installed in front of the nose landing gear. On this panel, 2 Lights indicate

the Ground Power Unit availability (AVAIL light) and connection to the

A/C network (NOT IN USE light). The Ground Power Unit should supply

400 Hz 3 phase 115 VAC rated at 90 kVA minimum.

The MAINTenance BUS SW, located on the forward cabin Circuit

Breaker (C/B) panel, lets the AC and DC service buses be supplied

without energizing the whole A/C electrical network.

The aft cabin C/B panel contains only C/Bs.

MAINTENANCE/TEST FACILITIES

The GAPCU is the interface between the GCUs and the Centralized Fault

Display Interface Unit (CFDIU) for test purposes and fault reporting on

the MCDUs. Both the BCLs and the EMER GCU communicate with the

CFDIU for the same purposes. The TRs are connected to the CFDIU so

that they can be reset via the MCDU.

SAFETY PRECAUTIONS

When you do any maintenance task on the electrical system, make sure

that no AC or DC power source is connected to the aircraft electrical

circuits.

Before De-energizing aircraft electrics or before doing the Static Inverter

test, tell all personnel on the aircraft that the lights will go out.

Some components are heavy. You must make sure that you can hold the

component before its removal/installation. If it falls, it can cause injury

to personnel and damage to the equipment.

Dangerous arcing can occur if external power (GPU or Gate power) is

energized when trying to connect power to the aircraft. Make sure that

external power source is de-energized before connecting.

Components can remain hot for one hour following engine shutdown.

Be careful as hot parts and hot oil can cause injury and burn your eyes

and skin. Use protective clothing, as oil products are poisonous.

ENVIRONMENTAL PRECAUTIONS

Turn-off unused ground service equipment (GPU, Air conditioning

cart, etc...) if no work is being done or nobody is present on the

aircraft.

SAFETY PRECAUTIONS - ENVIRONMENTAL PRECAUTIONS

0 Comments